Filimka Balaastikada ah wuxuu ka samaysan yahay PE, PP, PVC, PS, PET, PA, iyo resins kale, oo loo isticmaalo baakadaha dabacsan ama lakabka dahaarka, waxaana si weyn loogu isticmaalaa cuntada, daawada, kiimikooyinka, iyo meelaha kale, kuwaas oo baakadaha cuntadu ay yihiin kuwa ugu badan. Kuwaas waxaa ka mid ah filimka PE waa kan ugu badan ee la isticmaalo, waana kan ugu badan ee duubista balaastikada ah, kaasoo ka badan 40% isticmaalka filimka baakadaha balaastikada ah.

Inta lagu jiro diyaarinta filimada balaastikada ah, si loo hagaajiyo waxqabadkooda farsamaynta iyo cimriga adeegga, waxaa badanaa lagama maarmaan ah in lagu daro wakiilada simbiriirixan. wakiilada simbiriirixan waxay yareyn karaan isku-dhafka is-jiidjiidka ee dusha sare ee filimada balaastikada ah waxayna hagaajin karaan simanaantooda dusha sare, sidaas darteed waxay hagaajinayaan waxqabadkooda farsamaynta waxayna sii dheereynayaan cimrigooda adeegga.

Waqtigan xaadirka ah, wakiilada siligga caadiga ah waxaa ka mid ah amide, silicone polymer aad u sarreeya, copolymer polysiloxane, iwm. Noocyada kala duwan ee wakiilada siligga filimka waxay leeyihiin sifooyin iyo faa'iidooyin iyo khasaarooyin kala duwan, kan soo socdaa wuxuu si kooban u soo bandhigayaa dhowr wakiil oo siligga caadiga ah iyo sida loo doorto waxyaabaha lagu daro siligga ee Filimka Balaastikada:

Walxaha nuugista ee amide (oo ay ku jiraan aashitada oleic, aashitada erucic, iwm.):

Doorka ugu weyn ee waxyaabaha lagu daro amide ee wax soo saarka filimada polyolefin waa inay bixiyaan sifooyin simbiriirixan. Ka dib marka wakiilka simbiriirixan ee amide uu ka baxo caaryada, wakiilka simbiriirixan wuxuu isla markiiba u guuraa dusha sare ee filimka polymer-ka, marka uu gaaro dusha sarena, wakiilka simbiriirixanku wuxuu sameeyaa lakab saliidayn ah, kaas oo yareeya isku-dhafka oo gaara saameyn simbiriirixan.

- Faa'iidooyinka wakiilada sibidhka amide ee Filimka Balaastikada:

Qadar yar oo lagu daro diyaarinta filimka (0.1-0.3%), ayaa lagu daraa qaab isku dhaf ah ama masterbatch ah warshadda wax soo saarka si loo hubiyo saameyn siman oo isku mid ah; saameyn simitaan wanaagsan, waxay gaari kartaa isku dheelitirnaan hoose, qaddar aad u hooseeya ayaa buuxin kara shuruudaha.

- Qasaarooyinka wakiilada sibidhka amide ee Filimka Balaastikada:

Saamaynta daabacaadda:si dhakhso ah ayuu u soo degdegaa, taasoo keenta saameyn ku timaadda korona iyo daabacaadda.

Shuruudaha sare ee heerkulka cimilada: tusaale ahaan, tirada lagu daray xagaaga iyo jiilaalka way kala duwan tahay. Sababtoo ah heerkulka sare ee joogtada ah ee xagaaga, saliidaha sida erucic acid amide aad bay u fududahay in si joogto ah looga guuro dusha sare ee filimka, tirada u guurtay dusha sare ee filimkana waa la isku dari doonaa marka waqtigu sii socdo, taasoo horseedaysa kororka ceeryaamo filimka hufan, taasoo saameysa muuqaalka iyo tayada qalabka baakadaha. Waxay sidoo kale soo daadataa oo ku dhegtaa duubabka birta ah.

Dhibaatada kaydinta:Walaxaha simbiriirixan ee filimka Amide ayaa sidoo kale ka gudbi kara lakabka shaabadda kulaylka una gudbi kara lakabka corona ka dib marka filimka la nabareeyo iyo inta lagu jiro kaydinta dambe, taasoo si xun u saamaynaysa hawlaha hoose sida daabacaadda, dahaarka, iyo shaabadda kulaylka.

EBudada cad ee si fudud loo soo saari karo:Baakadaha cuntada, marka walaxda simbiriirixanaysa ay u guurto dusha sare, waxay ku milmi kartaa cuntada, taasoo saameynaysa dhadhanka oo kordhinaysa khatarta wasakhowga cuntada.

Wakiilada silikoon ee miisaanka molecular-ka aadka u sarreeya ee loogu talagalay Filimka Balaastikada:

Polysiloxane-ka miisaanka molecular-ka ee aadka u sarreeya wuxuu u janjeeraa inuu u guuro lakabka dusha sare, laakiin silsiladda molecular-ka aad bay u dheer tahay in si buuxda loo soo daayo, qaybta soo daadatayna waxay samaysaa lakab saliidayn ah oo silikoon ah oo dusha sare ah, taasoo keentay in la gaaro saameynta simbiriirixanka dusha sare.

- Faa'iidooyinka:

iska caabin heer-kul sare oo aad u fiican, roobab gaabis ah, gaar ahaan ku habboon khadadka baakadaha otomaatiga ah ee xawaaraha sare leh (sida filimka sigaarka).

- Qasaarooyinka:

hufnaan si fudud loo saameyn karo.

Inkasta oo waxyaabahan dhaqameed ee amide Slip Additives-ka ah si caadi ah loogu isticmaalo filimada balaastikada ah, warshaduhu ma lahan caqabado.

Sababo la xiriira halabuurka, astaamaha qaab-dhismeedka, iyo miisaanka yar ee molecular-ka, wakiilada simbiriirixan ee filimka Amide ee dhaqameed waxay aad ugu nugul yihiin roobab ama budo, taas oo si weyn u yareysa waxtarka wakiilka simbiriirixan, isku-dhafka is-jiidjiidku waa mid aan degganayn iyadoo ku xiran heerkulka, boolalkuna wuxuu u baahan yahay in si joogto ah loo nadiifiyo, waxayna sababi kartaa waxyeelo qalabka iyo badeecada.

Wax ka qabashada Caqabadaha Warshadaha Filimada Balaastikada:Xalka Hal-abuurka leh ee SILIKE

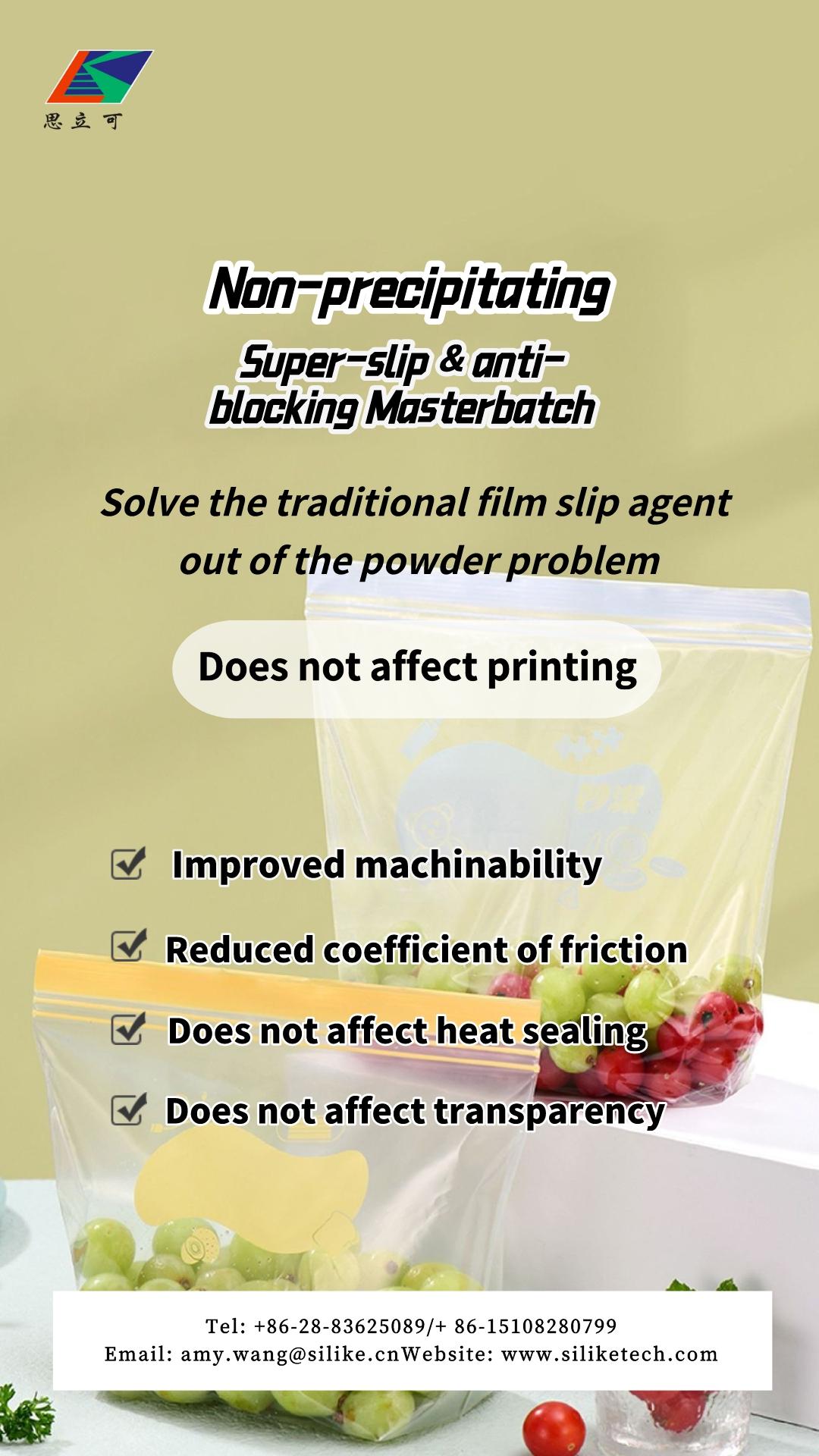

Si wax looga qabto caqabado badan oo la xiriira Waxyaabaha lagu daro Slip-ka ee dhaqanka ah ee loo isticmaalo soo saarista filimada balaastikada ah, gaar ahaan wakiilada siligga ee ku salaysan amide-ka dhaqameed. Kooxda cilmi-baarista iyo horumarinta ee SILIKE ayaa si guul leh wax uga qabatay arrimahan iyadoo horumarinaysaAgabyo Masterbatch ah oo aan simbiriirixan oo aad u qurux badan & ka-hortagga xannibaadda oo cusub- qayb ka mid ahTaxanaha SILIMER, kaas oo si wax ku ool ah u xalliya cilladaha wakiilka simbiriirixan ee dhaqameed, Aan u guurin lakabyada filimka, hubinta waxqabadka simbiriirixan ee deggan oo waara, kaas oo hal-abuur weyn u keenaya warshadaha Baakadaha Dabacsan ee Filimada Balaastikada. Horumarkan wuxuu bixiyaa faa'iidooyin sida saameyn yar oo ku saabsan daabacaadda, xidhitaanka kulaylka, gudbinta, ama ceeryaamo, oo ay weheliso CoF oo yar, ka hortagga xannibaadda wanaagsan, iyo hagaajinta simanka dusha sare, iyadoo meesha laga saarayo roobabka budada cad.

Taxanaha SILIMER Taxanaha Aan Daadashada Lahayn ee Super-simbirixan & Ka-hortagga Xannibaadda Masterbatchwaxay leedahay codsiyo kala duwan waxaana loo isticmaali karaa soo saarista filimada BOPP/CPP/PE/TPU/EVA, iwm. Waxay ku habboon yihiin tuurista, qaabaynta afuufidda, iyo hababka fidinta.

Maxaa sabab u ahTaxanaha SILIMER Aan roob badnayn oo ah Waxyaabaha lagu daro Masterbatch-ka ee aadka u simbiriirixan & ka hortagga xannibaaddama ka fiican yahay wakiilada simbiriirixan ee ku salaysan amide-ka caadiga ah?

Xalalka Hal-abuurka Tiknoolajiyada ee Xiiso leh ee Filimka Balaastikada ah

Polysiloxane-ka Copolymer-ka ah:SILIKE waxay soo saartay Additives Masterbatch ah oo aan soo jiidasho lahayn oo Super-slip & anti-blocking ah.- qayb ka mid ahTaxanaha SILIMER, kuwaas oo ah alaabada polysiloxane ee wax laga beddelay oo ka kooban kooxo firfircoon oo firfircoon oo organic ah, molecules-keedu waxay ka kooban yihiin labada qaybood ee silsiladda polysiloxane iyo silsiladda dheer ee kaarboon ee kooxaha firfircoon, silsiladda dheer ee kaarboon ee kooxaha firfircoon waxaa lagu xidhi karaa jir ahaan ama kiimiko ahaan resin-ka salka, waxay ciyaari karaan door xidhitaan ah, si loo gaaro saameynta fudud ee lagu guuri karo iyada oo aan roob lahayn, qaybaha silsiladda silikoon ee dusha sare, sidaas darteedna waxay ciyaarayaan saameyn siman.

Faa'iidooyinkaSILIKE SILIMER taxane ah oo aan daadanayn oo ah Waxyaabaha lagu daro Masterbatch-ka ee aadka u simbiriirixan & ka hortagga xannibaadda:

1. Xogta tijaabada ah waxay muujinaysaa in xaddi yar ooSILIKE SILIMER 5064MB1, iyoSILIKE SILIMER 5065HBsi wax ku ool ah ayuu u yareyn karaa isku-dhafka is-jiidjiidka wuxuuna yeelan karaa simbiriirixan waara oo deggan iyadoon loo eegin cimilada iyo heerkulka;

2. Ku daristaSILIKE SILIMER 5064MB1, iyoSILIKE SILIMER 5065HBinta lagu jiro diyaarinta filimada balaastikada ah saameyn kuma yeelanayso hufnaanta filimka mana saameynayso habka daabacaadda ee xiga;

3. Ku daristaSILIKE SILIMER 5064MB1, iyoSILIKE SILIMER 5065HBxaddi yar ayaa xalliya dhibaatada ah in wakiilada simbiriirixan ee amide-ka dhaqameed ay si fudud u daadan karaan ama u budo, waxay hagaajiyaan tayada badeecada, waxayna badbaadiyaan kharashka dhammaystiran.

Xasilloonida iyo hufnaanta sare eeTaxanaha SILIKE SILIMER ee Waxyaabaha Masterbatch-ka ee aan roobka lahayn ee Super-slip & anti-blockingWaxaan ka dhigay kuwo loo isticmaalo dhinacyo badan, sida soo saarista filimada balaastikada ah, filimka baakadaha isku dhafan, agabka baakadaha cuntada, soo saarista agabka baakadaha dawooyinka, iwm. SILIKE waxay sidoo kale siisaa macaamiisha xalal alaabeed oo la isku halleyn karo oo ammaan ah. Ma rabtaa inaad beddesho wakiilada simbiriirixanka amide ee gacantaada ku jira? Ma rabtaa inaad beddesho wakiilka simbiriirixanka amide ee Filimka Balaastikada ah, mise waxaad rabtaa inaad isticmaasho wakiil simbiriirixan oo ilaalin deegaan oo deggan oo hufan oo loogu talagalay Filimka Balaastikada ah, SILIKE waxay kugu soo dhaweyneysaa inaad nala soo xiriirto wakhti kasta, waxaanan rajeyneynaa inaan abuurno fursado badan adiga iyo adiga!

Waqtiga boostada: Jan-10-2024