Xilli ay heerarka iyo qawaaniinta badbaadada ay yihiin kuwa ugu muhiimsan, horumarinta agabka ka hortaga faafidda dabka ayaa noqotay qayb muhiim ah oo ka mid ah warshadaha kala duwan. Hal-abuurkan, isku-dhafka masterbatch-ka ee dab-damiska ayaa soo ifbaxay sidii xal casri ah oo lagu xoojinayo iska caabbinta dabka ee polymers-ka.

Fahmidda Waa maxay Isku-dhafka Masterbatch-ka ee ka hortagga dabka?

Isku-dhafka ugu fiican ee dab-damiska dabka waa qaacidooyin gaar ah oo loogu talagalay in lagu siiyo sifooyin u adkaysta dabka polymer-ka. Isku-dhafkan wuxuu ka kooban yahay resin side, kaas oo caadi ahaan ah polymer la mid ah walxaha salka, iyo waxyaabaha lagu daro dab-damiska dabka. Resin side wuxuu u adeegaa sidii dhexdhexaad lagu kala firdhiyo wakiilada dab-damiska dabka oo dhan oo ku baahsan matrix-ka polymer-ka.

Qaybaha Isku-dhafka Bacaha Dabka ee Ka-hortagga:

1. Resin-ka Xamuulka qaada:

Resin-ka side-ku wuxuu sameeyaa qaybta ugu badan ee masterbatch-ka waxaana lagu xushaa iyadoo lagu saleynayo iswaafajinta polymer-ka salka ah. Resin-ka side-ka caadiga ah waxaa ka mid ah polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), iyo thermoplastics kale. Doorashada resin-ka side-ku waa muhiim si loo hubiyo kala firdhinta wax ku oolka ah iyo iswaafajinta polymer-ka bartilmaameedka ah.

2. Waxyaabaha lagu daro ee ka hortaga ololka:

Waxyaabaha lagu daro waxyaabaha lagu daro ee dabka celiya waa walxaha firfircoon ee mas'uulka ka ah joojinta ama dib u dhigista faafitaanka dabka. Asal ahaan, waxyaabaha lagu daro waxay noqon karaan kuwo falcelin ah ama kuwo lagu daro. Waxyaabaha lagu daro waxaa loo kala saari karaa qaybo kala duwan, oo ay ku jiraan isku-dhisyo halogenated ah, isku-dhisyo ku salaysan fosfooraska, iyo kuwa lagu buuxiyo macdanta. Qayb kastaa waxay leedahay farsamo u gaar ah oo ay ku shaqeyso si loo xakameeyo habka gubashada.

2.1 Isku-dhafka Halogen-ka: Isku-dhafka Brominated iyo chlorine-ka ayaa sii daaya xagjirrada halogen inta lagu jiro gubashada, kuwaas oo farageliya falcelinta silsiladda gubashada.

2.2 Isku-dhafka ku salaysan fosfooraska: Isku-dhafkani wuxuu sii daayaa fosfooraska ama polyphosphoric acid inta lagu jiro gubashada, taasoo sameysa lakab ilaalin ah oo joojiya ololka.

2.3 Buuxiyaasha Macdanta: Buuxiyaasha aan dabiiciga ahayn sida aluminium hydroxide iyo magnesium hydroxide waxay sii daayaan uumiga biyaha marka ay la kulmaan kulaylka, iyagoo qaboojinaya walxaha iyo gaasaska guban kara.

3. Buuxiyaasha iyo Xoojinta:

Buuxiyaasha, sida talc ama calcium carbonate, ayaa badanaa lagu daraa si loo hagaajiyo sifooyinka farsamada ee isku-dhafka masterbatch-ka. Xoojinta waxay xoojisaa adkaanta, xoogga, iyo xasilloonida cabbirka, taasoo gacan ka geysaneysa waxqabadka guud ee maaddada.

4. Xasiliyayaal:

Xasiliyayaal ayaa lagu daray si looga hortago burburka matrix-ka polymer-ka inta lagu jiro farsamaynta iyo isticmaalka. Antioxidants iyo xasiliyeyaasha UV, tusaale ahaan, waxay gacan ka geystaan ilaalinta sharafta walxaha marka ay la kulmaan arrimo deegaan.

5. Midabada iyo Midabada:

Iyadoo ku xiran codsiga, midabeeyayaasha iyo midabyada ayaa lagu daraa si ay midabyo gaar ah ugu siiyaan isku-dhafka heerka sare. Qaybahani waxay sidoo kale saameyn karaan sifooyinka bilicda ee walxaha.

6. Kuwa iswaafajiya:

Xaaladaha ay dab-damiyeyaashu iyo matrix-ka polymer-ku muujiyaan is-waafajin liidata, waafajin ayaa la adeegsadaa. Wakiilladani waxay xoojiyaan isdhexgalka ka dhexeeya qaybaha, iyagoo kor u qaadaya kala-firdhinta wanaagsan iyo waxqabadka guud.

7. Daawooyinka Cabbiyaha Sigaarka:

Daawooyinka joojiya qiiqa, sida zinc borate ama molybdenum, mararka qaarkood waxaa lagu daraa si loo yareeyo soo saarista qiiqa inta lagu jiro gubashada, taas oo ah tixgelin muhiim ah oo ku saabsan codsiyada badbaadada dabka.

8. Waxyaabaha lagu daro ee loogu talagalay habaynta:

Qalabka wax lagu farsameeyo sida saliidaha iyowakiilada kala firdhiyaWaxay fududeeyaan habka wax soo saarka. Waxyaabaha lagu daro waxay hubiyaan in si habsami leh loo farsameeyo, laga hortago isku-darka, waxayna gacan ka geystaan gaarista kala-firdhinta isku midka ah ee waxyaabaha ka hortagaya ololka.

Kuwa kor ku xusan waa dhammaan qaybaha isku-dhafka dab-damiska dabka, halka Hubinta qaybinta siman ee dab-damiska dabka ee ku jira matrix polymer ah ay tahay qayb muhiim ah oo ka mid ah waxtarkooda. Kala-firdhinta aan ku filnayn waxay horseedi kartaa ilaalin aan sinnayn, sifooyin agab oo waxyeelleynaya, iyo yareynta badbaadada dabka.

Sidaa darteed, xeryahooda masterbatch-ka ee Flame retardant badanaa waxay u baahan yihiinfirdhiyeyaalsi wax looga qabto caqabadaha la xiriira kala firdhinta isku midka ah ee wakiilada ka hortagga ololka ee ku jira shaxda polymer-ka.

Gaar ahaan qaybta firfircoon ee sayniska polymer-ka, baahida loo qabo agabka horumarsan ee ka hortagga ololka oo leh sifooyin waxqabad sare leh ayaa kicisay hal-abuurro ku saabsan waxyaabaha lagu daro iyo wax-ka-beddelayaasha. Xalalka raadinta,hyperdispersantswaxay soo baxeen iyagoo ah ciyaartoy muhiim ah, iyagoo wax ka qabanaya caqabadaha ku saabsan gaaritaanka kala-fidinta ugu wanaagsan ee qaacidooyinka isku-dhafka Flame Retardant Masterbatch.

As hyperdispersantswax ka qabashada caqabaddan iyadoo la dhiirrigelinayo qaybinta dhammaystiran oo siman ee aaladaha dab-damiska ah ee ku baahsan xarunta masterbatch-ka.

Geli Hyperdispersant SILIKE SILIMER 6150—fasal lagu daro oo dib u habaynaya muuqaalka qaacidooyinka ka hortagga dabka!

SILIKE SILIMER 6150, waxaa loo sameeyay si loo daboolo baahiyaha gaarka ah ee warshadaha polymer-ka, Waa shamac silikoon ah oo wax laga beddelay.firfircoonida firfircoonida, waxay bixisaa xal loogu talagalay caqabadaha la xiriira gaaritaanka kala firdhinta ugu habboon iyo, sidaas darteed, badbaadada dabka ugu habboon.

SILIKE SILIMER 6150 ayaa lagula talinayaakala firdhinta midabada dabiiciga ah iyo kuwa aan dabiiciga ahayn iyo buuxinta, dab-celiyayaal ku jira qalabka thermoplastic masterbatch, TPE, TPU, elastomers kale oo thermoplastic ah, iyo codsiyada isku-dhafka ah. Waxaa loo isticmaali karaa noocyo kala duwan oo polymers thermoplastic ah oo ay ku jiraan polyethylene, polypropylene, polystyrene, ABS, iyo PVC.

SILIKE SILIMER 6150, Faa'iidada ugu weyn ee xeryahooda ka hortagga ololka

1. Hagaaji kala firdhinta dabka

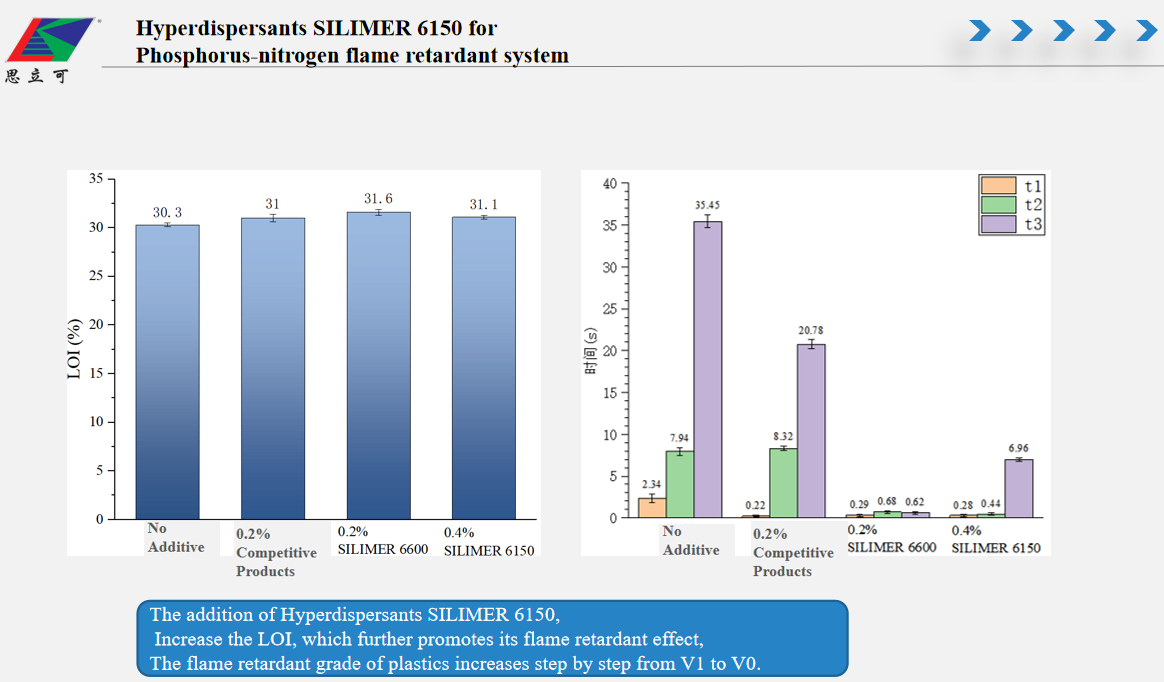

1) SILIKE SILIMER 6150 waxaa loo isticmaali karaa iyadoo lala kaashanayo masterbatch-ka fosfooraska-nitrogen-ka ee dab-damiska, si wax ku ool ah u hagaajinaya saameynta dab-damiska ee dab-damiska. Kordhinta LOI, dab-damiska g.rade ee balaastikada ayaa si tallaabo tallaabo ah u kordha V1 ilaa V0.

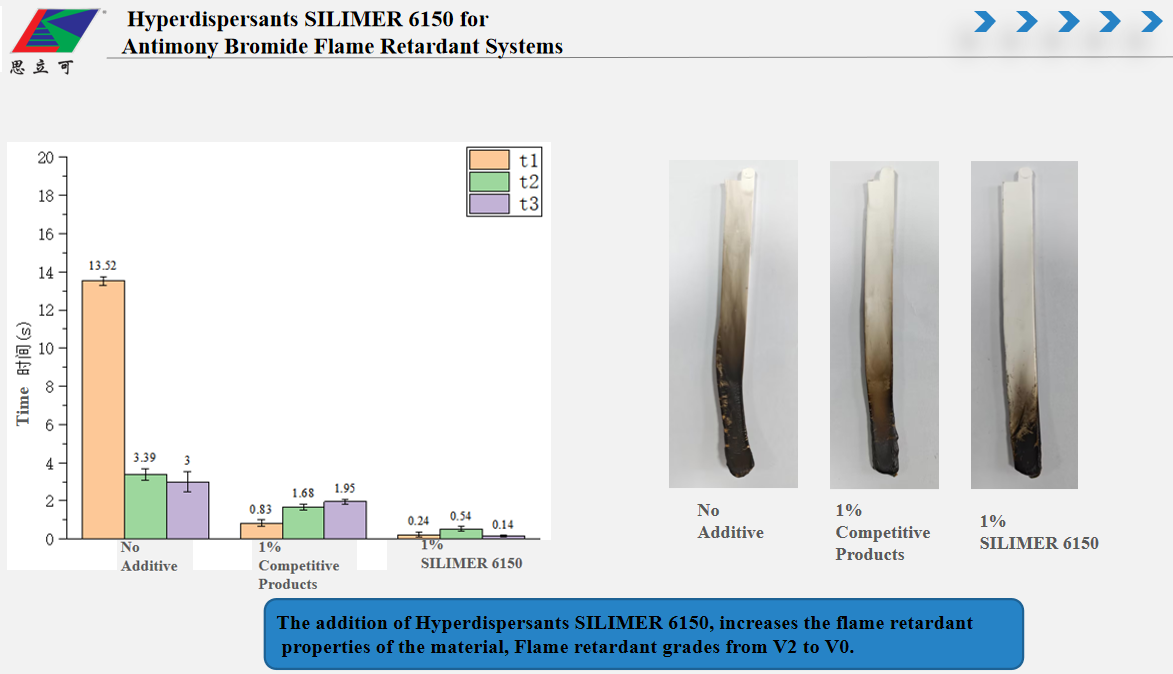

2) SILIKE SILIMER 6150 sidoo kale wuxuu leeyahay isku-dubarid wanaagsan oo dab-damis ah oo leh Nidaamyada Ka-hortagga Dabka ee Antimony Bromide, oo leh darajooyin dab-damis ah oo ka bilaabma V2 ilaa V0.

2. Hagaaji dhalaalka iyo simanka dusha sare ee alaabta (COF yar)

3. Heerarka qulqulka dhalaalka oo la hagaajiyay iyo kala firdhinta buuxinta oo la hagaajiyay, sii deynta caaryada oo wanaagsan iyo hufnaanta farsamaynta

4. Xoog midab oo la hagaajiyay, saameyn taban kuma yeelan sifooyinka farsamada.

La xiriir SILIKE si aad u aragto sida SILIMER 6150 Hyperdispersant ay uga caawin karto qaamuuska sameynta iskudhisyo cusub oo ka hortaga ololka iyo thermoplastics!

Waqtiga boostada: Oktoobar-23-2023