Xalalka Waxtarka leh ee Fiber-ka Sabeynaya ee ku jira Balaastikada Fiber-ka ee la xoojiyay.

Si loo hagaajiyo xoogga iyo iska caabbinta heerkulka alaabta, isticmaalka fiilooyinka galaaska si loo xoojiyo wax ka beddelka balaastikada ayaa noqday doorasho aad u wanaagsan, agabka galaaska lagu xoojiyay ee fiber-ka ayaa noqday mid aad u bisil warshadaha balaastikada. Tiro badan oo xaqiiqooyin ah ayaa sidoo kale caddeeyay waxqabadka wanaagsan ee fiber-ka galaaska keenay. Si kastaba ha ahaatee, fiber-ka galaaska iyo balaastiggu waa laba walxood oo kala duwan, kuwaas oo si dabiici ah u horseeda dhibaatooyin iswaafajin ah.

Soo-gaadhista faybarka galaaska (ama loo yaqaan faybar sabeynaya) waa mid si toos ah uga tarjumaysa iswaafajinta labada, waxayna si dhab ah u saamayn doontaa muuqaalka badeecada, taasoo keenta burburka alaabta. Soo-gaadhista faybarka galaaska sidoo kale waa dhibaato inta badan lagala kulmo habka wax-ka-beddelka duritaanka ee walxaha lagu daray faybarka waxayna dhibaato ku haysaa saaxiibo badan.

Haddaba sidee buu u dhacaa soo-gaadhista fiberglass-ka?

Buuxiyaasha faybarka waxaa lagu sameeyaa isku darka fiilooyinka galaaska iyo resin iyo granulating. Maadaama fiilooyinka galaaska ay aad uga yar yihiin dareeraha marka loo eego balaastikada, waxay ku sii jiri doontaa dusha sare ee caaryada inta lagu jiro farsamaynta, taasoo keenta in fiilooyinka galaaska la soo bandhigo. Isla mar ahaantaana, fiilooyinka galaaska waxay leeyihiin doorka kor u qaadista crystallization, PP iyo PA waa walxo crystalline ah. Crystallization si dhakhso ah ayuu u qaboojiyaa; si dhakhso ah ayuu u qaboojiyaa, fiilooyinka galaaska way adag tahay in lagu xidho resin iyo daboolka, ka dibna way fududahay in la soo saaro fiilooyinka galaaska la soo bandhigo.

Soo saarista Balaastikada Glass Fiber Reinforced Plastic, waxaa jira xalal kala duwan oo lagu hagaajinayo ifafaalaha "faybar sabeynaya":

1. Ka fiirso iswaafajinta fiber-ka galaaska iyo matrix-ka, daawaynta dusha sare ee fiber-ka galaaska, sida ku darista wakiil isku xidha iyo tallaal,

2. Kordhi heerkulka agabka iyo heerkulka caaryada; cadaadis sare iyo xawaare sare; isticmaal tignoolajiyada qaabaynta kulul iyo qabow ee degdega ah (RHCM),

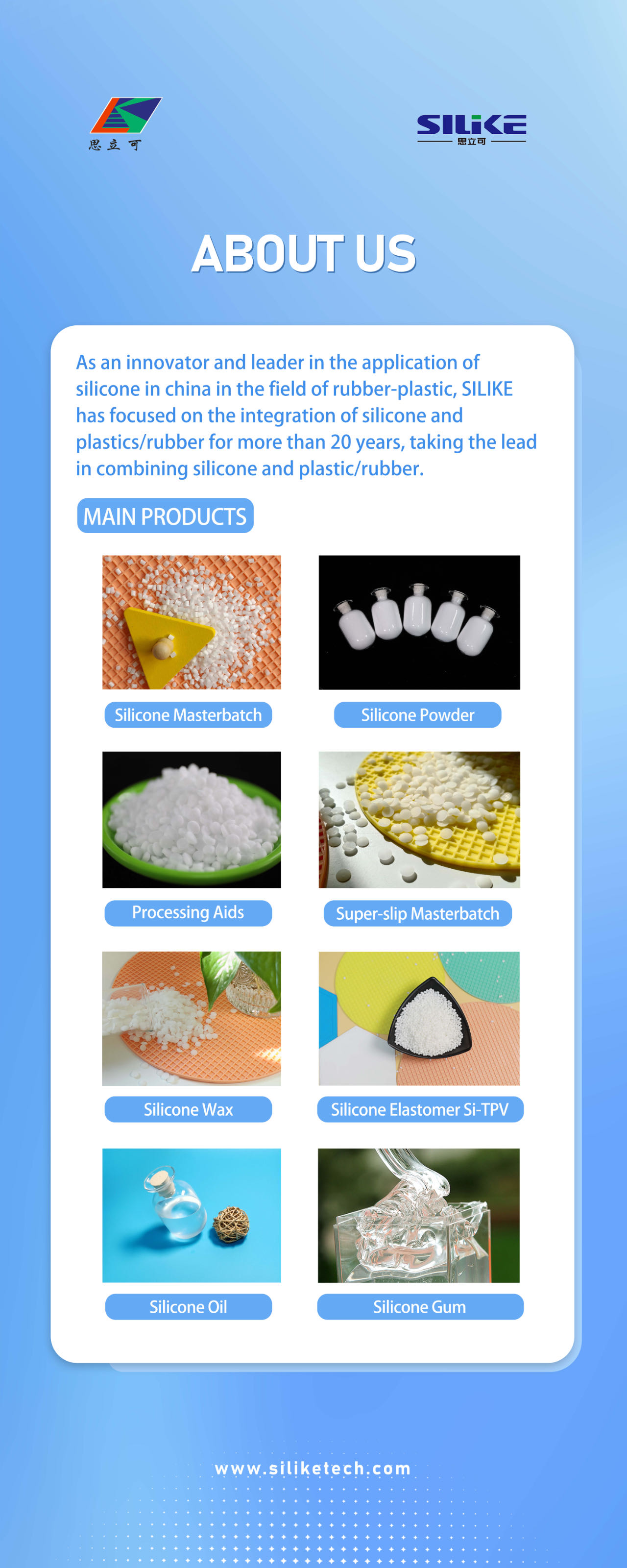

3. Ku darsaliidaha, waxyaabaha lagu daro waxay hagaajiyaan iswaafajinta isku xirka ee u dhexeeya fiber-ka galaaska iyo resin-ka, waxay hagaajiyaan isku-dhafka wejiga kala firdhisan iyo wejiga joogtada ah, waxay kordhiyaan xoogga isku xidhka isku xirka, waxayna yareeyaan kala-soocidda fiber-ka galaaska iyo resin-ka, taasoo hagaajinaysa soo-gaadhista fiber-ka galaaska.Waxyaabaha lagu daro silikoonwaxaa loo arkaa midka ugu waxtarka badansaliidSILIKE Technology waa shirkad cilmi baaris iyo horumarin madax-bannaan, oo isku-dhafan oo lagu ganacsado waxyaabaha lagu daro silicone ee Shiinaha, waxaa jira darajooyin badan ooWaxyaabaha lagu daro silikoon, oo ay ku jiraanTaxanaha LYSI ee Silikoon Masterbatch, Budada Silikoon Taxanaha LYSI, Silikoon oo ah qalab silikoon ah oo ka hortagga xoqidda,Taxanaha NM ee Silikoon ee Ka-hortagga Xasaasiyadda,Batch-ka ka hortagga qaylada,Batch-ka Super Slip Masterka,Si-TPV, iyo in ka badan, KuwaasWaxyaabaha lagu daro silikoonwaxay gacan ka geystaan hagaajinta sifooyinka farsamaynta ee agabka balaastikada ah iyo tayada dusha sare ee qaybaha la dhammeeyey.

Xalalka Wax Ku Oolka ah ee Maareynta Socdaalka Fiber-ka ee Balaastikada Muraayadda ee Fiber-ka La Xoojiyay—Budada Silikoonka ee SILIKEsi loo horumariyo soo-gaadhista Fiber-ka Muraayadda!

IsticmaalkaBudada silikoon ee SILIKEWaxaa la ogaaday in PA 6 oo leh 30% fiber galaas ah ay faa'iido leedahay, waxay si wax ku ool ah u yareyn kartaa is-dhexgalka molecular-ka, waxay hagaajin kartaa dareeraha dhalaalka, waxayna kor u qaadi kartaa kala-firdhinta waxtarka leh ee fiber galaas. Isla mar ahaantaana,Budada silikoon ee SILIKEwaxay leedahay iska caabin wanaagsan oo xoqid ah, xasillooni heerkul sare leh, iyo sifooyin aan guurin. Markaa, PA6 oo leh 30% fiber galaas ah oo ku jira habka farsamaynta heerkulka sare ma muuqan doonto coking iyo roobab ka yimaada walxaha molecular-ka hooseeya, si loo hubiyo in dhalaalka dusha sare ee badeecada, dhaqdhaqaaqa uu kordho, si fiber galaaska iyo PA6 loo dhalaali karo isla waqtigaas si loo xalliyo dhibaatada fiber-ka hirarka sababtoo ah dhalaalka dhacdada soo ifbaxday ee fiber galaaska ee dhacda waqti ka dib dusha sare ee caaryada si loo socodsiiyo, sidoo kale,Budada silikoonkawaxay sidoo kale kaa caawin kartaa yareynta qallooca iyo yaraanta inta lagu jiro wax soo saarka.

Wixii macluumaad dheeraad ah oo ku saabsanBudada Silikoonka ee SILIKEXalinta Arrimaha Fiber-ka ee Sabeynaya, ama taageero farsamo oo xirfadeed, fadlan nala soo xiriir!

Waqtiga boostada: Sebteembar-26-2023